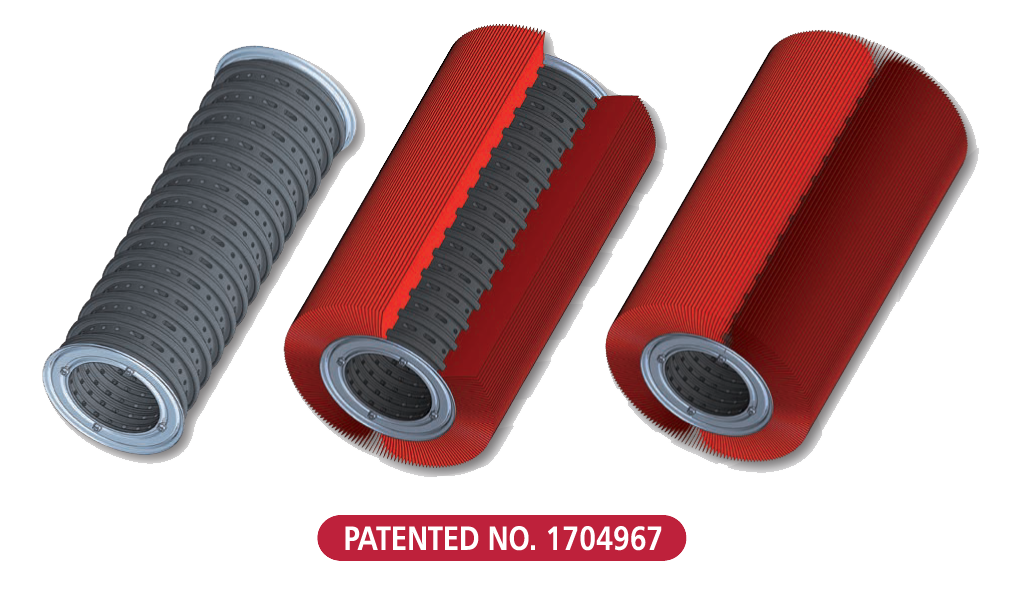

Our Development and Research Office designed and realised a new abrasive cloth tool that can work more than 30/35 meters per second.

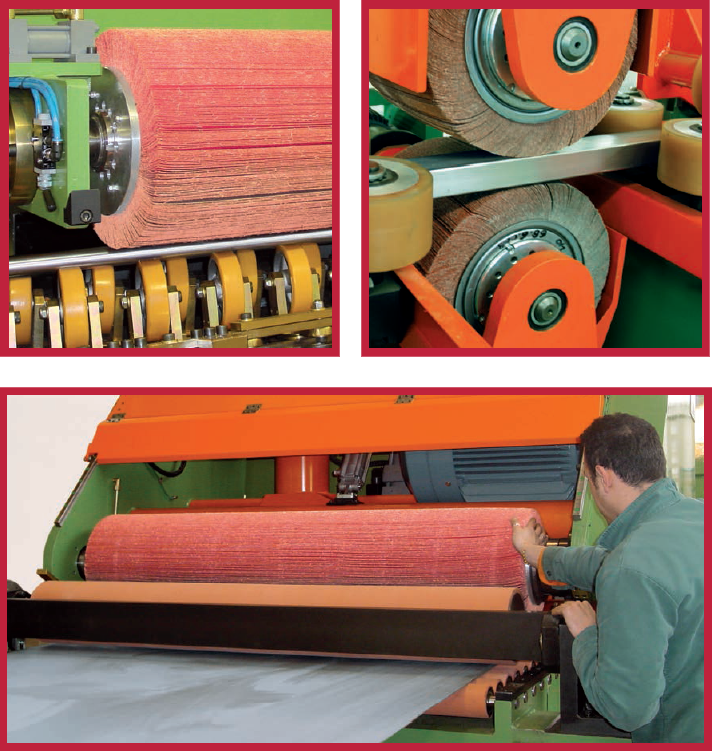

The peculiarity of the new method allows the constant maintaining of the peripheral speed and the pressure on the bar/tube/sheet/coil during the whole cycle of working of the same: the result is therefore the perfect and homogeneous of the all worked surface.

The new-patented system has re-built (revolutionized) the traditional “belt” one.

PRO

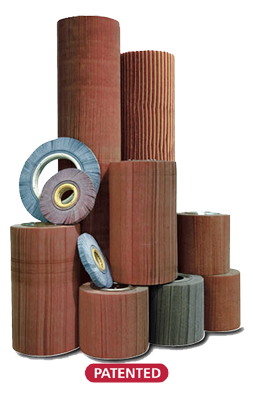

Machine downtime for replacement of worn-out is reduced.

While the tool is getting worn-out, both the peripheral speed and the working pressure are kept constant all the time by the electronic system provided on the line.

Uniform finish for the entire duration of the treatment.

Dry machining: the process is run without the use of cooling water or oil, assuring low working temperatures and easy cleaning of the machine itself, avoiding the necessity to take care of the sludge.

The flap wheel can be air cooled both inside and outside, which permits complete dry working of the materials (no water usage).

High reduction of roughness on hot rolled material in a single go.

REDUCTION OF PRDODUCTION AND MAINTENANCE COSTS BY 50%

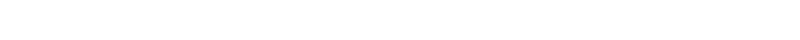

The new flap wheel can be used for:

- SATIN FINISHING

- SCOTCH BRITE FINISHING

- “COMBI” FINISHING

- SUPER MIRROR FINISHING